Upgrading your Tevo Tarantula’s X axis is a fantastic way to improve print quality, reduce issues, and enhance the overall performance of your 3D printer. This guide will walk you through the entire process, from understanding the current X axis to installing a new, improved one. Whether you’re a beginner or an experienced maker, this comprehensive guide provides detailed instructions and tips to ensure a successful upgrade. By following these steps, you’ll transform your Tevo Tarantula into a more reliable and precise 3D printing machine. Let’s dive in and elevate your 3D printing experience with this essential upgrade.

Understanding the Tevo Tarantula X Axis

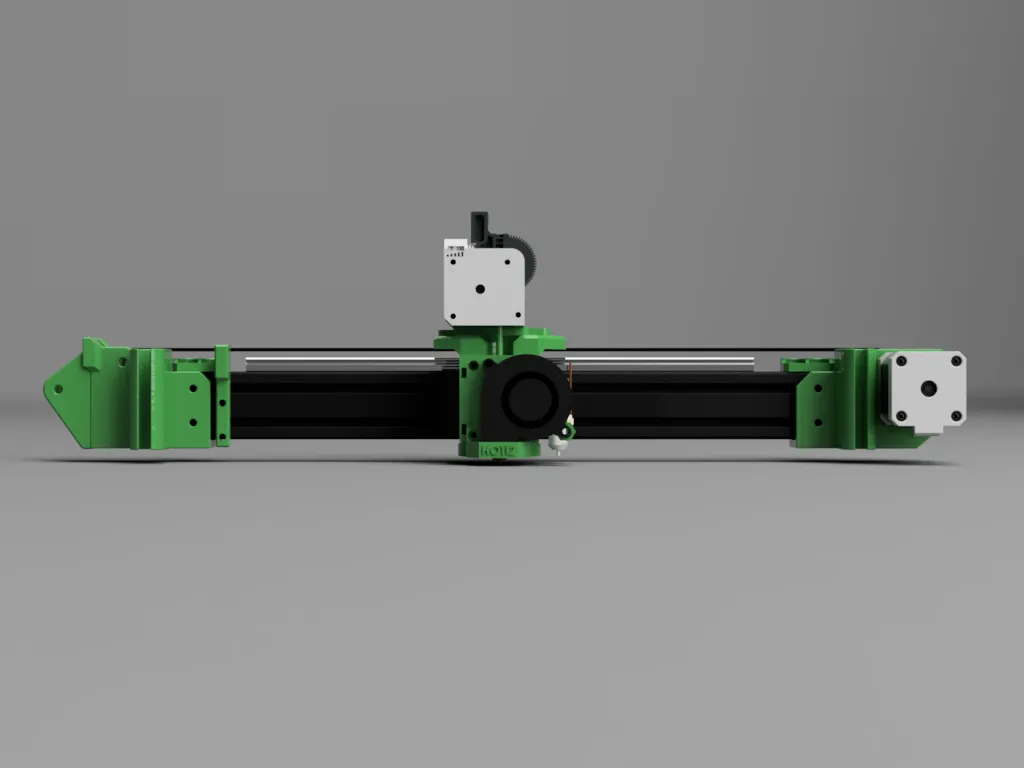

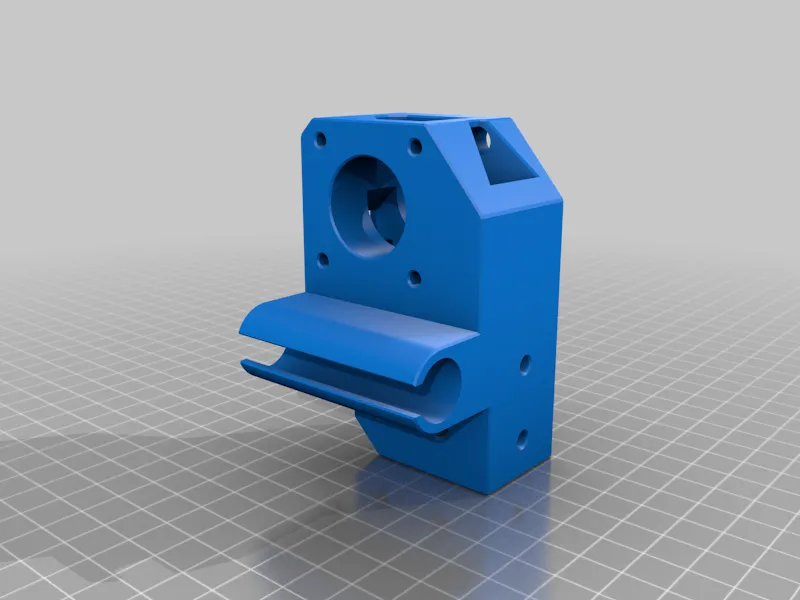

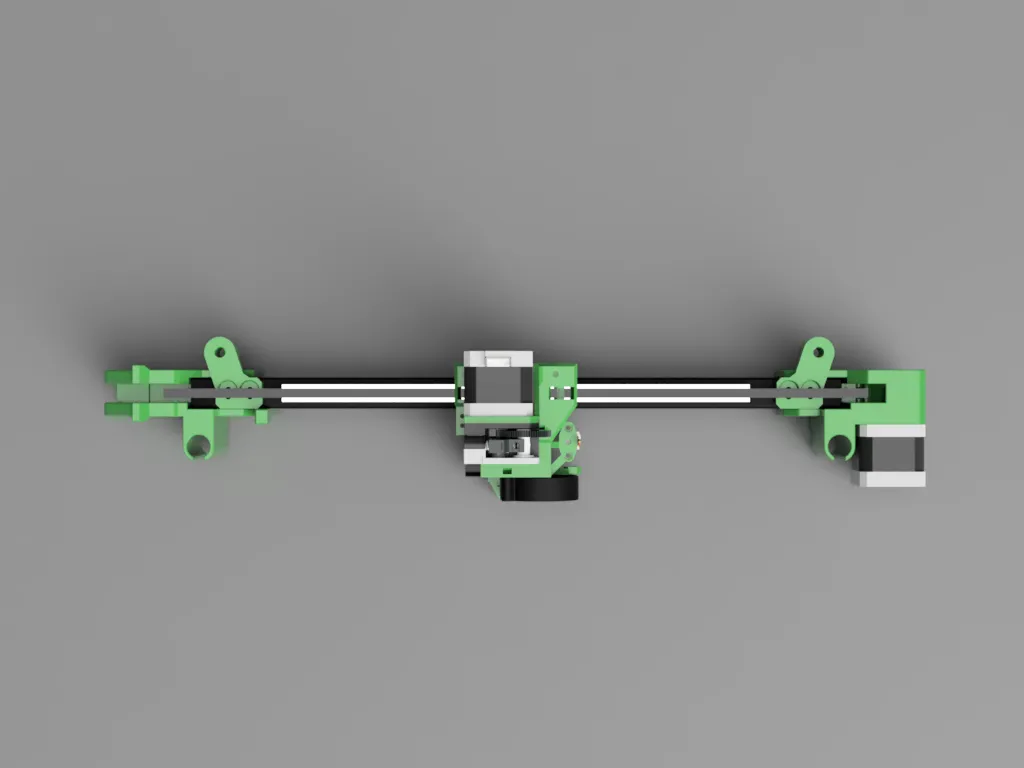

The X axis of the Tevo Tarantula is responsible for the horizontal movement of the print head, which is critical for the accuracy and quality of your prints. It comprises several key components, including the X-axis stepper motor, the X-axis belt, pulleys, linear bearings, and the carriage that holds the hotend. Understanding how these components work together is crucial for identifying potential problems and knowing where improvements can be made. The original design of the Tevo Tarantula’s X axis often uses plastic parts, which can be prone to wear, flex, and vibration, ultimately affecting print quality. Proper alignment and tension of the belt and other components are essential for smooth and precise movement.

Identifying the Need for an X Axis Upgrade

Before starting the upgrade, it’s essential to determine if it’s necessary. Common signs that indicate the need for an X axis upgrade include print defects such as layer shifting, banding, or inconsistent dimensions. These issues often stem from a wobbly or unstable X axis. Additionally, if you notice excessive noise or vibration during printing, or if the print head struggles to move smoothly, an upgrade could be beneficial. Consider the materials you typically print with; higher-temperature filaments like ABS and PETG can exacerbate issues with the original X axis design. If you aim to increase printing speed without compromising quality, an upgrade is almost certainly a worthwhile investment.

Common Problems with the Tevo Tarantula X Axis

The Tevo Tarantula’s original X axis design is susceptible to several common problems that can lead to poor print quality. One of the most frequent issues is the use of plastic parts, which can flex and deform under stress, leading to inaccuracies in movement. Belt tension can be difficult to maintain, causing slippage and layer shifting. Furthermore, the linear bearings may wear out or become misaligned over time, causing friction and reducing the smoothness of movement. The stock stepper motor might not be powerful enough for fast printing or heavier print heads, leading to missed steps and imperfections. These problems are amplified when printing at higher speeds or with materials that require higher printing temperatures.

Benefits of Upgrading the X Axis

Upgrading your Tevo Tarantula’s X axis offers numerous benefits that can significantly improve your 3D printing experience. Firstly, you’ll notice a marked improvement in print quality, with reduced layer shifting, more consistent dimensions, and smoother surfaces. Secondly, an upgraded X axis often uses sturdier materials, like aluminum extrusions or carbon fiber rods, resulting in greater stability and reduced vibration, which in turn makes your prints more precise. Additionally, the upgrade can increase printing speed without sacrificing quality, allowing you to complete projects faster. Finally, it will extend the lifespan of your 3D printer by reducing wear and tear on key components and reducing noise and improving overall performance.

Materials and Tools Required for the Upgrade

Before you begin, gather all the necessary materials and tools to ensure a smooth and successful upgrade. You’ll need an X-axis upgrade kit, which usually includes new linear rails, bearings, a belt, and possibly a new carriage and stepper motor. The specific kit you choose will depend on your budget and the level of improvement you desire. You will also need a set of hex keys (Allen wrenches), a screwdriver, pliers, a ruler or calipers for precise measurements, and a level. Consider having a small container or tray to organize screws and small parts. It’s also helpful to have some zip ties for cable management and a good quality lubricant to ensure smooth movement of the new components.

Gathering the Necessary Components

Procuring the right components is a crucial step in the upgrade process. Start by researching various X-axis upgrade kits available for the Tevo Tarantula. These kits often come with everything you need, including linear rails, bearings, a belt, and sometimes even a new carriage or stepper motor. Check online marketplaces like Amazon or specialized 3D printing stores for options. Consider the materials used in the upgrade kit; aluminum extrusions or carbon fiber rods offer greater stability and precision. Ensure the kit is compatible with your specific Tevo Tarantula model and any modifications you might have made. Compare prices, read reviews, and choose a kit that meets your needs and budget.

Selecting the Right Upgrade Kit

Choosing the right upgrade kit is critical for a successful X-axis upgrade. Consider your printing needs and budget when making your selection. Higher-quality kits often include upgrades such as linear rails instead of the original V-slot wheels, reducing the wobble and improving print precision. Look for kits with well-regarded brands or positive reviews. Check the materials used in the kit; aluminum extrusions or carbon fiber rods offer greater stability. Ensure the kit is compatible with your specific Tevo Tarantula model. Read reviews and compare prices to find a kit that offers the best value for your money, considering the benefits of improved print quality, reduced noise, and faster printing speeds.

Disassembling the Old X Axis

Before you can install the new X axis, you must carefully disassemble the old one. Begin by unplugging your 3D printer from the power source and removing the hotend and any attached components, such as fans or sensors, taking care to disconnect all the wires. Next, detach the X-axis belt from the carriage and motor. Then, unscrew the X-axis assembly from the frame of the 3D printer. Carefully remove the old X-axis components, noting the position and orientation of each part. Take photos during disassembly to serve as a reference for reassembly if needed. Keep all the screws and hardware organized and safely stored, and this will facilitate the reassembly process.

Removing the Existing Components

Once the X-axis assembly is detached, focus on removing the existing components. Start by removing the stepper motor and the pulleys. Carefully detach any wires connected to the hotend and other components mounted on the carriage. Remove the linear bearings or wheels, and if present, any mounting brackets. Take care not to damage any of the original parts. Clean the frame and any surfaces that will be in contact with the new components. Keep all the original screws and parts organized, as some may be needed for the new assembly. Check the condition of any existing wiring and replace any damaged wires during the process. This is a good time to assess the overall condition of the printer and make any necessary repairs.

Preparing the 3D Printer for New Parts

Before installing the new X axis components, prepare the 3D printer frame to ensure a clean and accurate installation. Clean the frame and any surfaces where the new components will be mounted. Remove any old grease or debris. Ensure the frame is square and level, as any misalignment will affect the print quality. If necessary, use a level to check the frame’s alignment and make any adjustments. Verify that the mounting points for the new X-axis components are clear and free of obstructions. It may be necessary to lightly sand or file the frame to ensure a good fit. Taking the time to prepare the frame properly will help ensure the new X axis operates smoothly and precisely.

Installing the New X Axis Components

With the printer prepared, begin installing the new X-axis components. Following the instructions provided with your upgrade kit, carefully mount the linear rails or rods onto the frame. Ensure they are perfectly aligned and securely fastened. Attach the new carriage, ensuring it moves smoothly along the rails or rods. Mount the stepper motor and pulleys according to the kit’s instructions. Properly tension the X-axis belt, ensuring it’s not too tight or too loose. Install any additional components, such as endstops or cable management clips. Double-check all screws and connections to ensure they are secure. Refer to the upgrade kit instructions and photos taken during disassembly for guidance, and don’t hesitate to make adjustments as needed.

Assembling the New X Axis

Assembling the new X axis is a crucial step in the upgrade process, so precise attention to detail is paramount. Start by carefully fitting the linear bearings or wheels onto the carriage, making sure they are properly aligned and secured. Install the hotend carriage onto the new X-axis assembly, ensuring smooth movement along the linear rails or rods. Attach the X-axis belt to the carriage and the stepper motor pulley. Ensure the belt is properly tensioned, but not overly tight, as this can cause premature wear. Double-check all screws and fasteners to ensure they are securely tightened. Before moving on, manually slide the carriage along the X-axis to check for any binding or friction, and adjust as needed.

Wiring and Connecting the New Components

Properly wiring and connecting the new components is essential for the functionality of your upgraded X axis. Carefully connect the stepper motor to the appropriate terminals on the mainboard. If the new motor has different wiring, consult the documentation to ensure correct polarity and connection. Reconnect the endstop switch, ensuring it is correctly positioned and triggered when the print head reaches the end of its travel. Properly secure all wires using cable management techniques like zip ties or wire looms to prevent them from interfering with moving parts. Check all connections for secureness and shorts. After wiring, test the movement of the X axis using the printer’s control panel or software to confirm the components are functioning correctly.

Calibrating the X Axis after Upgrade

Once the new X axis is installed and wired, calibrate it to ensure accurate and reliable printing. Start by calibrating the X-axis steps per millimeter in your printer’s firmware. You can calculate this by measuring the distance the print head moves for a given command. Adjust the settings in your printer’s firmware or slicing software accordingly. Then, level the print bed precisely, making sure the nozzle is the correct distance from the bed across the entire printing surface. Finally, perform a test print of a calibration cube or a similar test object to verify the X axis accuracy and identify any remaining issues. Make small adjustments to the calibration settings if needed until you achieve the desired results.

Adjusting Stepper Motor Drivers

Adjusting the stepper motor drivers is essential for optimal performance of your upgraded X axis. Stepper motor drivers control the amount of current supplied to the stepper motors. Incorrect current settings can lead to missed steps, overheating, and poor print quality. Locate the stepper motor drivers on your 3D printer’s mainboard. Use a multimeter to measure the voltage across the potentiometer on each driver and adjust the voltage to the recommended value for your stepper motor. Adjust the drivers with care, making small incremental changes and testing the X axis movement after each adjustment. Ensure the stepper motors don’t overheat during operation. Proper adjustments will reduce noise and improve the smoothness of your prints.

Leveling the Print Bed

Proper bed leveling is critical for achieving high-quality prints with your upgraded X axis. Start by manually leveling the print bed using the adjustment screws or knobs, ensuring the nozzle is the correct distance from the bed at all four corners. Then, use the printer’s auto-leveling feature, if equipped, to create a mesh of the bed’s surface. Fine-tune the bed level during printing by adjusting the Z-offset in your slicing software or on the printer’s control panel. After leveling, perform a test print, such as a first-layer test, to verify the level and make any necessary adjustments. Consistent bed leveling ensures the first layer adheres properly and reduces warping and other print defects.

Testing and Troubleshooting the Upgrade

After completing the X-axis upgrade and calibration, it’s time to test the improvements. Start by running several test prints, such as calibration cubes, small geometric shapes, and models with intricate details. Monitor the print quality closely, looking for any imperfections like layer shifting, inconsistent dimensions, or surface irregularities. If you encounter issues, carefully review the assembly and calibration steps, checking for any loose connections, misalignment, or incorrect settings. Use the troubleshooting tips below to identify and resolve common problems. Document the issues and solutions to refer to in the future. Fine-tuning your setup during testing is essential for optimizing performance.

Running Test Prints

Running test prints is a critical step in evaluating the effectiveness of the X-axis upgrade. Select a variety of test prints, including a calibration cube to check dimensions, a bridging test to evaluate overhang performance, and detailed models to assess print quality. During the test prints, observe the print head’s movement, listening for any unusual noises or vibrations. Examine the printed parts for any signs of layer shifting, warping, or other defects. Adjust your printing settings, such as speed, temperature, and retraction, based on the results of the test prints. Keep detailed notes of your print settings and any modifications, to help you fine-tune your setup for optimal performance.

Troubleshooting Common Issues

Even with careful installation, you may encounter issues. If you experience layer shifting, check the belt tension, stepper motor driver settings, and the alignment of the X axis. If the X axis is noisy, ensure the linear bearings are lubricated and the rails are clean. If the print quality is poor, check the nozzle temperature, bed level, and filament quality. If the stepper motor skips steps, reduce the print speed or increase the stepper motor driver current. Carefully review all connections, ensuring they are secure and correctly wired. Consult online forums and communities for troubleshooting assistance and solutions specific to the Tevo Tarantula.

Tips for Maintaining Your Upgraded X Axis

Proper maintenance will ensure the longevity and optimal performance of your upgraded X axis. Regularly lubricate the linear rails and bearings with a suitable lubricant to reduce friction and wear. Check the belt tension periodically and adjust as needed to prevent slippage. Keep the X-axis assembly clean and free of debris. Inspect the wiring and connections for any signs of damage or wear. Regularly clean your 3D printer and maintain the components to keep your Tevo Tarantula in good condition. Periodic maintenance and care will help you maintain your prints and your printer.

Congratulations! You’ve successfully upgraded your Tevo Tarantula’s X axis. By following this guide, you’ve taken a significant step in improving print quality, reducing common issues, and enhancing the overall performance of your 3D printer. Enjoy your upgraded 3D printing machine, and keep experimenting and refining your skills. Happy printing!